Understanding the Hidden Danger

Asbestos represents one of the most dangerous building materials ever used in construction. This naturally occurring mineral fiber was popular in buildings from the 1940s through the 1980s because it resisted heat, fire, and chemicals. Builders used asbestos in thousands of products, from insulation to floor tiles.

The health risks connected to asbestos exposure are severe and life-threatening. When asbestos fibers become airborne, people can breathe them into their lungs. These tiny fibers stay trapped in lung tissue for decades, causing serious diseases like mesothelioma and lung cancer.

Professional removal becomes critical when asbestos materials get damaged or disturbed. DIY removal attempts often make contamination worse by releasing more fibers into the air. Trained specialists have proper equipment and knowledge to remove asbestos safely without spreading contamination.

The remediation process involves careful planning, containment, removal, and disposal. Each step requires specialized training and equipment to protect workers and building occupants from dangerous fiber exposure.

Identifying Asbestos in Your Property

Common Locations Where Asbestos Hides

Asbestos appears in many building materials throughout older properties. Insulation materials pose the biggest threat, especially in attics, walls, and around pipes. The fluffy, gray-white insulation around boilers and ducts often contains high levels of asbestos.

- Flooring materials frequently contain asbestos, particularly vinyl tiles and the backing on old linoleum floors. These materials become dangerous when they crack, chip, or get sanded during renovation projects.

- Roofing and siding materials from older buildings often contain asbestos cement. Shingles, corrugated panels, and flat roofing materials may release fibers when they weather or get damaged.

- Textured paints and coatings applied before 1980 commonly contained asbestos. Popcorn ceilings, textured wall finishes, and some spray-on coatings pose risks when they get scraped or sanded.

- HVAC ductwork and components in older systems may have asbestos insulation or gaskets. Heating system components, duct connectors, and boiler insulation need careful inspection.

- Cement products and wallboards in pre-1980 buildings might contain asbestos fibers. Cement siding, millboard, and some drywall compounds included asbestos for strength.

Age-Based Risk Assessment

Buildings constructed before 1980 carry the highest risk of asbestos contamination. During this period, manufacturers widely used asbestos in hundreds of building products without understanding the health dangers.

Materials from 1980-1990 present moderate risk as the construction industry slowly phased out asbestos use. Some products continued to contain asbestos even after manufacturers knew about health risks.

Post-1990 construction rarely contains asbestos, but imported materials and specialty products might still pose risks. Even newer buildings can have asbestos if renovated with older materials or if contractors used remaining old stock.

Property owners should suspect asbestos presence in any building materials that are over 40 years old, especially if the materials show signs of wear, damage, or previous disturbance.

Health Risks and Medical Implications

Asbestos-Related Diseases

- Mesothelioma stands as the most deadly asbestos-related disease. This rare cancer affects the lining around lungs, heart, or abdomen. Most mesothelioma cases link directly to asbestos exposure, and the prognosis remains poor with survival rates under five years.

- Asbestosis causes permanent scarring of lung tissue that makes breathing increasingly difficult. This progressive disease develops after years of fiber buildup in the lungs. People with asbestosis face higher risks of heart problems and lung cancer.

- Lung cancer rates increase significantly among people exposed to asbestos. The risk multiplies for smokers who also face asbestos exposure. These cancers often develop 20-40 years after initial exposure.

- Pleural diseases affect the membrane surrounding the lungs. Pleural plaques, fluid buildup, and thickening can cause chest pain and breathing problems. While often non-cancerous, these conditions indicate asbestos exposure occurred.

Exposure Pathways and Risk Factors

- Inhalation of microscopic fibers represents the primary danger from asbestos exposure. These invisible fibers float in air for hours and travel deep into lung tissue when breathed.

- Cumulative exposure effects mean that even small amounts of asbestos over time can cause disease. No safe level of asbestos exposure exists, making any contact potentially dangerous.

- Latency periods for disease development range from 10-50 years after initial exposure. This long delay makes it difficult to connect health problems to past asbestos contact.

- High-risk occupations include construction workers, mechanics, shipyard workers, and renovation specialists. These jobs involve regular contact with materials that might contain asbestos.

Vulnerable Populations

- Children face special risks because their developing lungs are more sensitive to fiber damage. Even brief exposure during childhood can lead to disease decades later.

- Elderly individuals with existing health problems may develop asbestos diseases more quickly. Their immune systems often cannot handle the additional stress from fiber exposure.

- Workers in renovation and construction face the highest exposure risks during their careers. These professionals need proper training and protective equipment to stay safe.

- Family members of exposed workers can develop diseases from secondhand exposure. Workers who carry asbestos fibers home on clothing and tools put their families at risk.

Legal Requirements and Regulations

Federal Regulations and Oversight

- EPA regulations control how asbestos gets removed, handled, and disposed of across the country. The Environmental Protection Agency sets strict standards for who can remove asbestos and how they must do it.

- OSHA workplace safety standards protect workers during asbestos removal projects. The Occupational Safety and Health Administration requires specific training, equipment, and procedures for worker protection.

- Clean Air Act requirements limit how much asbestos can be released into the environment. These rules apply to demolition, renovation, and disposal activities that might disturb asbestos materials.

- Toxic Substances Control Act provisions regulate the manufacture, use, and disposal of asbestos products. This law helps prevent new asbestos contamination while managing existing materials.

State and Local Regulations

- Licensing requirements for contractors vary by state but typically include specialized training and certification programs. Only licensed professionals should handle asbestos removal projects.

- Permit processes and notifications require advance notice to local authorities before asbestos work begins. These systems help track removal projects and protect public safety.

- Disposal regulations and approved facilities control where asbestos waste can go after removal. Special landfills with proper containment systems accept asbestos materials.

- Inspection and monitoring requirements may mandate air testing before, during, and after asbestos work. These tests verify that removal projects stay within safety limits.

Liability Considerations

- Property owner responsibilities include identifying asbestos hazards and hiring qualified contractors for removal work. Owners who ignore asbestos problems face legal and financial risks.

- Contractor licensing and insurance requirements protect property owners and workers from liability. Always verify that asbestos contractors carry proper credentials and coverage.

- Documentation and compliance records must be kept for years after asbestos work gets completed. These records prove that removal followed proper procedures.

- Penalties for improper handling can include heavy fines and criminal charges. Illegal asbestos disposal or unsafe removal practices carry serious legal consequences.

Safe Asbestos Removal Procedures

Containment and Isolation Methods

- Work area sealing creates barriers that prevent asbestos fibers from spreading to other parts of a building. Plastic sheeting and tape form airtight seals around the work zone.

- Negative air pressure systems use powerful fans and filters to pull air out of the work area. This prevents contaminated air from flowing into clean areas of the building.

- HEPA filtration requirements mandate high-efficiency filters that capture 99.97% of particles. These filters remove asbestos fibers from air before it gets released outside.

- Access control and decontamination areas provide safe entry and exit points for workers. Multiple chambers allow workers to remove contaminated equipment before leaving the work zone.

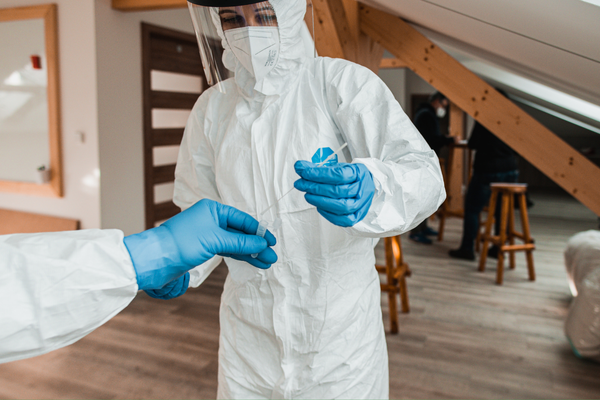

Personal Protective Equipment (PPE)

- Respiratory protection systems supply clean air to workers through full-face masks or supplied-air systems. These devices prevent workers from breathing contaminated air.

- Disposable protective clothing covers workers from head to toe during asbestos work. These suits get disposed of as hazardous waste after each use to prevent contamination spread.

- Glove and footwear requirements include materials that resist tearing and provide good grip. Multiple layers of gloves may be needed for different tasks.

- Decontamination procedures remove asbestos fibers from workers and equipment before they leave the work area. Special washing stations and disposal areas support these procedures.

Removal Techniques by Material Type

- Wet removal methods spray water or special solutions onto asbestos materials before removal. This prevents fibers from becoming airborne during the removal process.

- Careful dismantling procedures avoid breaking or damaging asbestos materials during removal. Gentle techniques reduce fiber release compared to aggressive removal methods.

- Specialized tools and equipment help remove asbestos safely without creating dust or debris. Hand tools often work better than power tools that might spread fibers.

- Waste containerization and labeling puts removed asbestos into sealed containers marked with hazard warnings. Proper packaging prevents accidental exposure during transport and disposal.

Air Monitoring During Removal

- Real-time fiber monitoring tracks airborne asbestos levels throughout the removal process. Electronic monitors provide instant feedback about contamination levels.

- Personal exposure assessment measures how much asbestos individual workers might breathe during their shifts. Personal monitors help verify that protective equipment works properly.

- Area sampling protocols check air quality in different parts of the building during asbestos work. These tests confirm that containment systems prevent contamination spread.

- Clearance testing requirements verify that asbestos levels return to safe levels after removal work gets completed. Independent testing confirms that areas are safe for normal use.

Disposal and Transportation Requirements

Approved Disposal Facilities

- EPA-approved landfill requirements specify which disposal sites can accept asbestos waste. These facilities have special containment systems to prevent environmental contamination.

- Manifest and tracking documentation follows asbestos waste from removal site to final disposal. This paper trail helps regulators track hazardous materials and prevent illegal dumping.

- Transportation regulations and licensing require special permits and training for hauling asbestos waste. Not all waste haulers can legally transport asbestos materials.

Cost factors for disposal depend on distance to approved facilities and the amount of material being disposed of. Remote locations may face higher disposal expenses.

Waste Packaging Specifications

- Double-bagging requirements put asbestos waste into two layers of specially marked plastic bags. This redundant packaging prevents leaks during transport and handling.

- Leak-tight container standards specify container materials and sealing methods that prevent asbestos release. Rigid containers may be required for certain types of materials.

- Labeling and warning requirements mandate specific hazard symbols and text on asbestos waste containers. These warnings protect handlers and disposal workers from accidental exposure.

Size and weight limitations prevent containers from becoming too heavy or awkward to handle safely. Proper sizing reduces the chance of container damage during transport.

Transportation Protocols

- Licensed hauler requirements mandate special training and permits for companies that transport asbestos waste. Regular waste haulers cannot legally carry asbestos materials.

- Route restrictions and notifications may limit which roads can be used for asbestos transport. Some jurisdictions require advance notice of hazardous waste shipments.

- Emergency response procedures prepare for accidents or spills during asbestos transport. Specialized cleanup crews and equipment may be needed for transportation incidents.

- Documentation and record keeping tracks every step of the disposal process from removal to final burial. These records prove proper handling if questions arise later.

Post-Removal Verification and Clearance

Clearance Testing Procedures

- Visual inspection requirements check that all visible asbestos materials have been removed from the work area. Trained inspectors look for any remaining contaminated materials.

- Air sampling protocols collect air samples from the work area and compare them to background levels. Multiple samples from different locations provide better accuracy.

- Laboratory analysis and reporting examines air samples under powerful microscopes to count asbestos fibers. Certified laboratories provide official results for regulatory compliance.

- Multi-phase testing may require several rounds of sampling over time. Initial tests verify removal completion while follow-up tests confirm long-term safety.

Acceptable Clearance Levels

- Fiber concentration standards set maximum allowable asbestos levels in air after removal work. These standards protect building occupants from harmful exposure.

- Background level comparisons measure asbestos in outdoor air and uncontaminated parts of the building. Indoor levels should not exceed normal background concentrations.

- Seasonal and regional variations account for natural differences in background asbestos levels. Testing protocols adjust for local conditions that might affect results.

- Quality assurance measures include duplicate samples and blank controls to verify testing accuracy. These procedures catch errors that might affect clearance decisions.

Re-occupancy Procedures

- Clearance certificate requirements provide official documentation that areas are safe for normal use. Building owners need these certificates before allowing people back into remediated areas.

- HVAC system cleaning and testing removes any asbestos contamination from heating and cooling systems. Ductwork and equipment may need special cleaning after removal work.

- Final documentation and records compile all testing results, procedures, and certifications into permanent files. These records prove compliance with regulations and protect against future liability.

- Long-term monitoring considerations may require periodic retesting to verify continued safety. Some situations warrant ongoing surveillance to detect any remaining contamination.

Emergency Response Procedures

Accidental Disturbance Protocols

- Immediate area evacuation moves people away from accidentally disturbed asbestos materials. Quick evacuation prevents exposure while response teams assess the situation.

- Contamination containment seals off disturbed areas to prevent asbestos spread. Emergency containment may use plastic sheeting and tape to isolate contaminated zones.

- Professional assessment requirements bring qualified experts to evaluate accidental disturbances. Only trained professionals can determine proper cleanup procedures for each situation.

- Cleanup and remediation procedures follow the same safety protocols as planned removal projects. Emergency cleanups require the same containment, protection, and disposal methods.

Exposure Incident Management

- Medical evaluation recommendations advise people who might have been exposed to asbestos during accidents. Early medical consultation helps establish baseline health records.

- Documentation and reporting requirements record details about exposure incidents for regulatory agencies and insurance companies. Thorough documentation protects against future liability.

- Insurance notification procedures alert property insurance carriers about asbestos incidents that might lead to claims. Early notification helps preserve coverage rights.

- Long-term health monitoring may be recommended for people exposed during accidents. Medical surveillance can detect early signs of asbestos-related diseases.

Communication and Notification

- Occupant notification procedures inform building users about asbestos incidents and safety measures. Clear communication prevents panic while keeping people informed about risks.

- Regulatory reporting requirements mandate notifications to environmental and health agencies about asbestos releases. These reports help authorities track contamination incidents.

- Insurance company coordination involves property insurers in incident response and cleanup decisions. Early involvement helps manage costs and coverage issues.

- Public health authority involvement brings local health departments into serious exposure incidents. These agencies help protect community health and provide medical guidance.

Technology and Innovation in Asbestos Management

Advanced Detection Methods

- Portable testing technologies allow faster identification of asbestos in building materials. Handheld devices can provide preliminary results within minutes rather than days.

- Real-time fiber monitoring systems track airborne asbestos levels continuously during removal work. These systems provide immediate warnings if containment fails.

- Improved sampling techniques increase accuracy while reducing testing costs. New methods can detect lower fiber concentrations with better reliability.

- Digital documentation and tracking create electronic records that are easier to store and search. Digital systems help manage complex projects with multiple testing phases.

Removal Technology Improvements

- Enhanced containment systems provide better isolation of work areas with less setup time. Modular containment units can be quickly deployed for emergency response.

- Improved protective equipment offers better protection with greater comfort for workers. Lighter, more breathable suits and better air supply systems reduce worker fatigue.

- Automated removal equipment reduces worker exposure by performing some removal tasks remotely. Robotic systems can handle the most dangerous removal operations.

- Waste processing innovations compact asbestos waste more efficiently and safely. New packaging systems reduce disposal volumes while maintaining safety standards.

Future Regulatory Developments

- Proposed rule changes may tighten standards for asbestos detection and removal. Regulatory agencies continue to evaluate current rules and consider improvements.

- International best practices adoption brings lessons from other countries to improve domestic asbestos management. Global cooperation helps develop better safety standards.

- Technology-driven compliance tools use software and monitoring equipment to verify regulatory compliance. Automated systems can track and report compliance activities more accurately.

- Industry standard evolution adapts to new scientific knowledge about asbestos risks and removal techniques. Professional standards continue to improve as understanding advances.

Conclusion

Safe asbestos management requires following key principles that protect health and property values. Professional expertise makes the difference between safe, compliant removal and dangerous contamination spread.

Content Restoration Services brings over 25 years of experience to asbestos challenges in Charlotte, NC. The company follows all federal and state regulations while using advanced techniques and equipment for safe removal.

Professional asbestos services protect both immediate health and long-term property values. Proper removal eliminates liability risks while creating safer environments for families and workers. Content Restoration Services provides expert asbestos removal services that meet all regulatory requirements.

Property owners facing asbestos concerns should never attempt DIY removal or ignore potential hazards. Content Restoration Services offers complete restoration solutions that address asbestos safely and effectively.

After asbestos removal, properties may need additional services like post-construction cleaning to address renovation debris. Content Restoration Services can also handle reconstruction projects that restore properties to better-than-original condition.

Contact Content Restoration Services today for professional asbestos assessment and removal services in Charlotte, NC. Protecting your health and property starts with proper asbestos management by qualified experts.